Koalstofstiel Sekkantbout Din 933

| Produktnamme | KOALSTOFSTIJL SEKSKANTBOUT DIN 933/ISO4017 |

| Standert | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Klasse | Stielkwaliteit: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Ofmeitsjen | Sink (Giel, Wyt, Blau, Swart), Hop Dip Galvanisearre (HDG), Swart Oksyde, Geomet, Dacroment, anodisaasje, Nikkel platearre, Sink-Nikkel platearre |

| Produksjeproses | M2-M24: Kâld smeden, M24-M100 hjit smeden, Bearbeitings- en CNC-bewerking foar oanpaste befestigingsmiddelen |

| Oanpaste produkten levertiid | 30-60 dagen, |

| Fergese samples foar standert befestiging | |

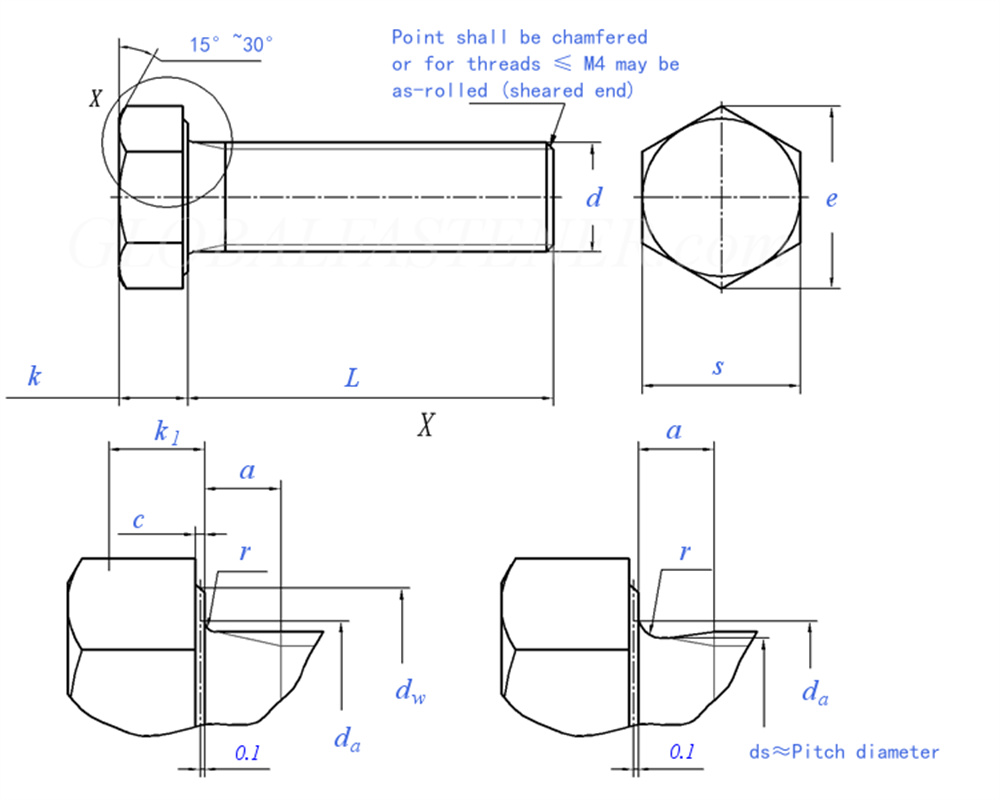

| Skroefdraad | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Toanhichte | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| a | maks | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 4 | 4.5 | 5.3 | |

| min | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| c | maks | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | maks | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| dw | Klasse A | min | 2.27 | 3.07 | 4.07 | 4.57 | 5.07 | 5.88 | 6.88 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Klasse B | min | 2.3 | 2.95 | 3.95 | 4.45 | 4,95 | 5.74 | 6.74 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Klasse A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Klasse B | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| k | Nominale grutte | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Klasse A | maks | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4,95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Klasse B | maks | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Klasse A | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Klasse B | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | maks = nominale grutte | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Klasse A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Klasse B | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Skroefdraad | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Toanhichte | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| a | maks | 6 | 6 | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | |

| min | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | ||

| c | maks | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | maks | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| dw | Klasse A | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Klasse B | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59,95 | |

| e | Klasse A | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Klasse B | min | 22.78 | 26.17 | 29.56 | 32,95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| k | Nominale grutte | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Klasse A | maks | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Klasse B | maks | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Klasse A | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Klasse B | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | maks = nominale grutte | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Klasse A | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Klasse B | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Skroefdraad | (M45) | M48 | (M52) | M56 | (M60) | M64 | ||||||||

| P | Toanhichte | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |||||||

| a | maks | 13.5 | 15 | 15 | 16.5 | 16.5 | 18 | |||||||

| min | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | ||||||||

| c | maks | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

| da | maks | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 | |||||||

| dw | Klasse A | min | - | - | - | - | - | - | ||||||

| Klasse B | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 | |||||||

| e | Klasse A | min | - | - | - | - | - | - | ||||||

| Klasse B | min | 76,95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |||||||

| k | Nominale grutte | 28 | 30 | 33 | 35 | 38 | 40 | |||||||

| Klasse A | maks | - | - | - | - | - | - | |||||||

| min | - | - | - | - | - | - | ||||||||

| Klasse B | maks | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 | |||||||

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | ||||||||

| k1 | Klasse A | min | - | - | - | - | - | - | ||||||

| Klasse B | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 | |||||||

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 | |||||||

| s | maks = nominale grutte | 70 | 75 | 80 | 85 | 90 | 95 | |||||||

| Klasse A | min | - | - | - | - | - | - | |||||||

| Klasse B | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |||||||

Eigenskippen en foardielen

Koalstofstiel Sekkantbout Din 933: De oplossing foar jo befestigingsbehoeften

As it giet om befestiging, wolle jo in oplossing dy't stevich, betrouber en maklik te ynstallearjen is. Koalstofstiel Hex Bolt Din 933 foldocht oan alle easken troch in duorsume en alsidige bout oan te bieden dy't brûkt wurde kin foar in breed skala oan tapassingen.

Dizze bout is makke fan heechweardich koalstofstiel en is ûntworpen om rûge omjouwings, hege spanning en swiere lesten te wjerstean. De hexagonale kop soarget foar in feilige en strakke fit, wylst de tried maklik te ynstallearjen en te ferwiderjen is.

Dizze bout, mei in lingte fan 6 mm oant 100 mm, is te krijen yn in ferskaat oan maten om te foldwaan oan ferskate projekten en easken. Oft jo no in masine bouwe, in struktuer oprjochtsje of apparatuer oaninoar befestigje, dizze bout biedt de sterkte en fearkrêft dy't jo nedich binne om de baan dien te krijen.

Boppedat is koalstofstiel heksagonbout Din 933 maklik te ûnderhâlden en ferslitst net maklik mei de tiid. Dit betsjut dat jo nei ynstallaasje jierrenlang op syn effektiviteit fertrouwe kinne.

Foar dyjingen dy't op syk binne nei in bout dy't sawol betelber as fan hege kwaliteit is, is dizze bout fan koalstofstiel in perfekte kar. It elimineert net allinich de needsaak foar djoere en yngewikkelde befestigingsoplossingen, mar it is ek maklik te ynstallearjen en te ferwiderjen, wêrtroch jo weardefolle tiid en muoite besparje.

Gearfetsjend is de koalstofstiel heksagonbout Din 933 in tige betroubere en praktyske befestigingsoplossing dy't brûkt wurde kin yn in ferskaat oan tapassingen. It is ûntworpen foar maksimale duorsumens en gebrûksgemak, wêrtroch it in goede kar is foar sawol yngenieurs, bouwers as DIY-entûsjasters. Fertrou op de koalstofstiel heksagonbout Din 933 om jo in oplossing te bieden dy't oan alle easken foldocht, nettsjinsteande hokker projekt jo wurkje.